FAQ – Antworten zu Solarthemen: Solarzellen, Solarmodule & Solarindustrie

Are you interested in solar energy? So are we! And that’s why we’re renewing our research laboratory.

Here you can see how you can help us!

what is a solar cell and what is it made of?

A solar cell, also known as a photovoltaic cell, converts sunlight directly into electricity. It consists mainly of silicon (made from quartz sand), which has semiconductor properties. When light hits the solar cell, electrons are set in motion, which generates electricity. Detailed information on ISC cell technology can be found here.

How are solar modules constructed?

Solar modules consist of several solar cells that are arranged in rows and columns and interconnected. This arrangement is embedded between a stable rear side and a transparent front side, often made of glass. The modules are fitted with electrical connections to dissipate the electricity. The entire construction is designed to protect the cells and maximize their service life. Would you like to know more? Find out all about ISC module technology.

how are solar cells and modules manufactured?

The production of solar cells begins with the cleaning and melting of silicon, which is then cast into blocks and sawn into thin slices known as wafers. These wafers are chemically treated to optimize the semiconductor properties and add electrical contacts. The cells are then assembled into modules by interconnecting, laminating and framing them.

how much energy is consumed in the production of solar cells and modules?

The amount of energy required to manufacture solar cells and modules depends on the technology used and the manufacturing process. Modern solar modules amortize the energy used for production within approximately one year, depending on the location and operating conditions.

How much energy can a solar module generate?

The amount of energy a solar panel can generate depends on several factors, including the efficiency of the solar cells, the size of the panel and the amount of sunlight at the location. On average, 1KWp (kilowatt peak) solar module system in Germany can generate around 800 to 1,200 kilowatt hours (kWh) of electricity per year, which can cover the average electricity consumption of a single household. For complex solar systems, the expected yield can be calculated using our yield forecasting software, for example. For simple systems, for example, the freely accessible solar calculator is suitable.

What is the aim of the LIBERTAS study?

The LIBERTAS study is funded by the German Federal Ministry of Economics and Climate Protection (BMWK) and carried out by RCT Solutions, the ISC Konstanz and the VDMA. It aims to identify measures that are necessary to revive a significant solar industry in Germany and Europe. The aim is to establish a complete ecosystem of production, mechanical engineering, supply chains and research & development. Find out more here.

Why is it important to reestablish the PV industry in Germany?

The reestablishment of the PV industry in Germany is of strategic importance for the energy transition and energy independence. A strong local industry strengthens the German economy, creates jobs, promotes innovation and reduces dependencies on totalitarian states and international markets in general. Germany can also strengthen its position as a technology leader and contribute to reducing CO2 emissions.

how does Germany compare internationally in terms of PV production?

Currently, PV production is mainly concentrated in China, with well over 90% of global capacity. Germany and Europe are striving to increase their own production capacity in order to reduce dependency and strengthen competitiveness.

why are production capacities in the PV industry in China so much higher than in European countries?

Production capacities in the PV industry in China are significantly higher than in European countries due to several key factors.

- China identified the solar industry as a strategic economic target at an early stage and has therefore invested in the solar industry. In some cases, aggressive government support measures such as subsidies, tax incentives and a favorable political landscape have been created to promote the development and expansion of PV production.

- The Chinese PV industry is now benefiting from economies of scale resulting from large production volumes and the integrated value chain, which are significantly reducing manufacturing costs.

- In addition to strong exports, China has a strong domestic demand for solar energy, which is supported by national renewable energy targets.

This combination of government support, economies of scale and strong demand has made China one of the world’s leading manufacturers of solar technology. Europe, and Germany in particular, could produce at comparable costs or even more cheaply through the use of innovations if there were an ecosystem with a solar industry of the same size as in China. Germany knows very well how to produce!

Which technologies are considered in solar cell production?

Current technologies include n-type silicon cells, which will account for more than 50% of the market from 2024. The study also looks at advanced technologies such as tandem solar cells, which can achieve efficiencies of over 30%. Learn more about the ISC technologies.

What are the challenges and solutions for the solar industry in Germany?

Challenges include higher production costs compared to China and the need for a complete value chain. Solutions include investment subsidies, resilience bonuses ideally within the framework of the EEG and the establishment of pilot lines for the rapid development of innovations from research and development by industry or institutes.

what are investment subsidies and how do they support the development of the solar industry in Germany?

Investment incentives are financial incentives such as grants or tax concessions that companies receive for the construction or expansion of production facilities in the solar industry. The aim of these subsidies is to reduce the initial capital costs for setting up production capacities and thus improve competitiveness compared to countries with lower production costs. Investment subsidies create incentives for companies to invest in local production facilities, which not only creates jobs and strengthens the local economy, but also increases independence from imports. The LIBERTAS study proposes such subsidies as part of a comprehensive package of measures to establish a sustainable ecosystem for the solar industry in Germany and Europe.

What is the resilience bonus and how does it work?

The costs of manufacturing solar modules in Europe are currently higher than the production costs in China. This is due to the fact that much less is produced here than in China (economies of scale), as described in answer 9. A “baby-care” is needed: the establishment of local production must first be supported with running costs – an ecosystem can be built up in which production is worthwhile without subsidies. The resilience bonus is part of the support measures proposed in the LIBERTAS study. It compensates for the difference in manufacturing costs between local and international production. It is intended to support the start-up of local production and promote the sustainability of PV manufacturing in Germany.

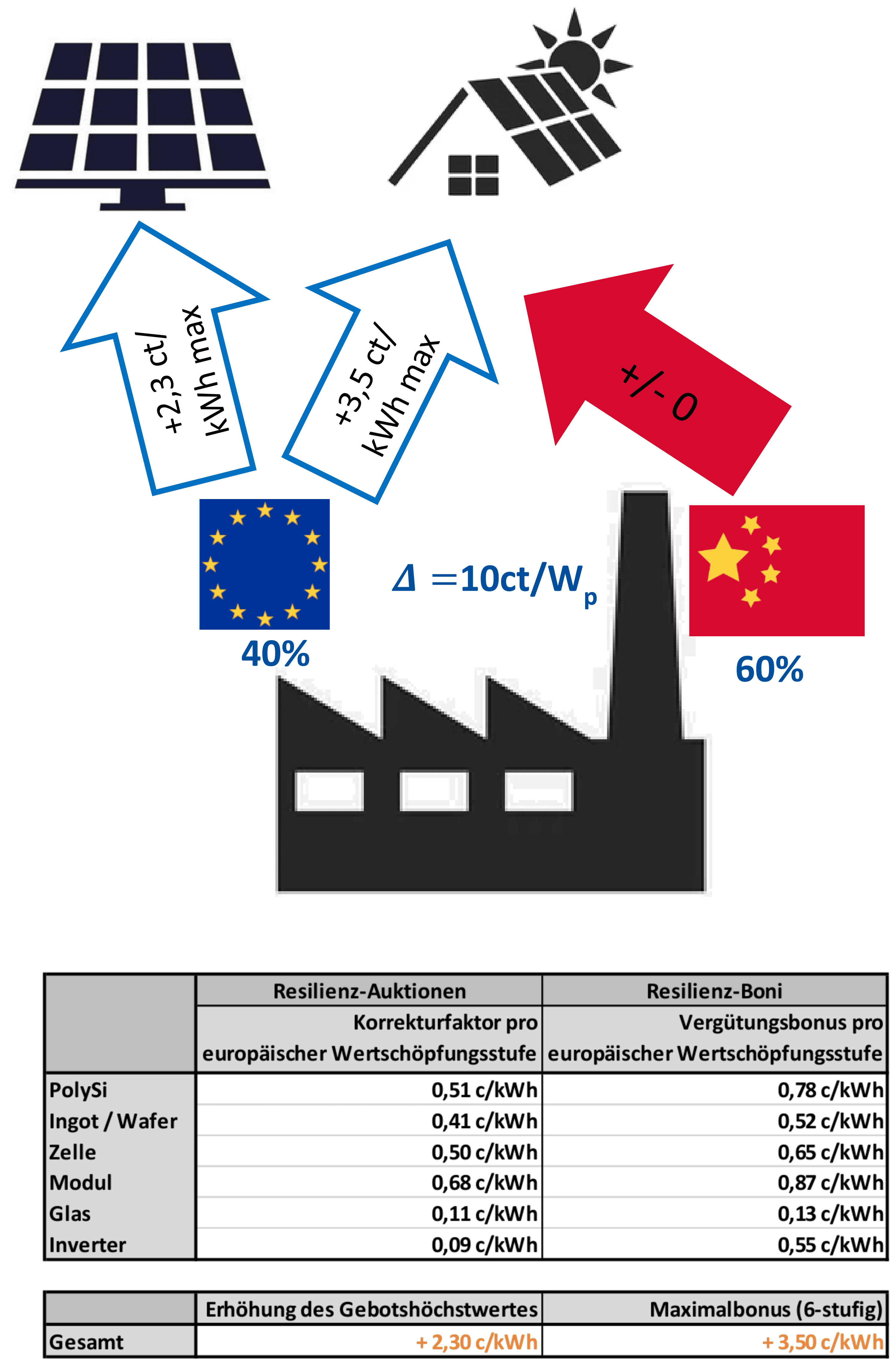

This is a summary of the proposal from the BSW – Bundesverband Solarwirtschaft e.V. (German Solar Industry Association) – it helps to bring them back to Germany with manageable effort.

The problem:

- China is currently producing more cheaply than manufacturers in Europe could. Because there is hardly any PV industry and supply chains left here. In addition, subsidies and price wars are leading to sales below production costs.

Facts about the resilience bonus:

- The resilience bonus should be part of the EEG. EEG costs have been financed from the KTF since 2023. The costs are therefore not passed on to the electricity price.

- Anyone who feeds solar power into the grid will (as before) receive remuneration in accordance with the EEG.

- Those who also use modules manufactured locally (in Europe) will receive more remuneration: graduated according to the proportion of local components (see table below).

- The resilience bonus should be possible for a maximum of 9 GW of modules. This means that up to 40% of the 22GW annual PV growth planned in Germany will come from local production! Everyone can continue to use components from China – but will then receive no or less resilience bonus.

That’s why this helps us:

- With the resilience bonus, the local PV industry can re-establish itself! We were able to show this at the ISC Konstanz together with RCT Solutions GmbH in the LIBERTAS study.

- The resilience bonus will only make up a small proportion of the EEG. The additional costs of the resilience bonus amount to 40 million to 680 million euros per year.

what role do research and development (R&D) play in the future of the solar industry?

Research and development in the solar industry are crucial for overcoming technical limits, reducing production costs and introducing new technologies. Germany is well positioned to play a leading role with many recognized top institutes. The next generation of solar cells, when today’s dominant crystalline solar cell technology reaches its physical limits, will be tandem technologies with efficiencies of 30% and more. The ISC Konstanz and other German research institutes have been working on these developments for years and are showing top results: we are prepared!

How can interested parties and experts contribute to the revival of the solar industry in Germany?

Interested parties can invest in solar energy by disseminating information and . Experts can get involved in R&D, promote cooperation with industry and research institutions and drive innovation. You can find out how you can support us here.

Vorstand, Geschäftsführer

Tel.: +49-7531-36183-22